HEPA/ULPA air filter

Initial pressure drop, initial efficiency and filter classification for HEPA/ULPA filter

Testing standards:

Initial pressure drop

Initial efficiency

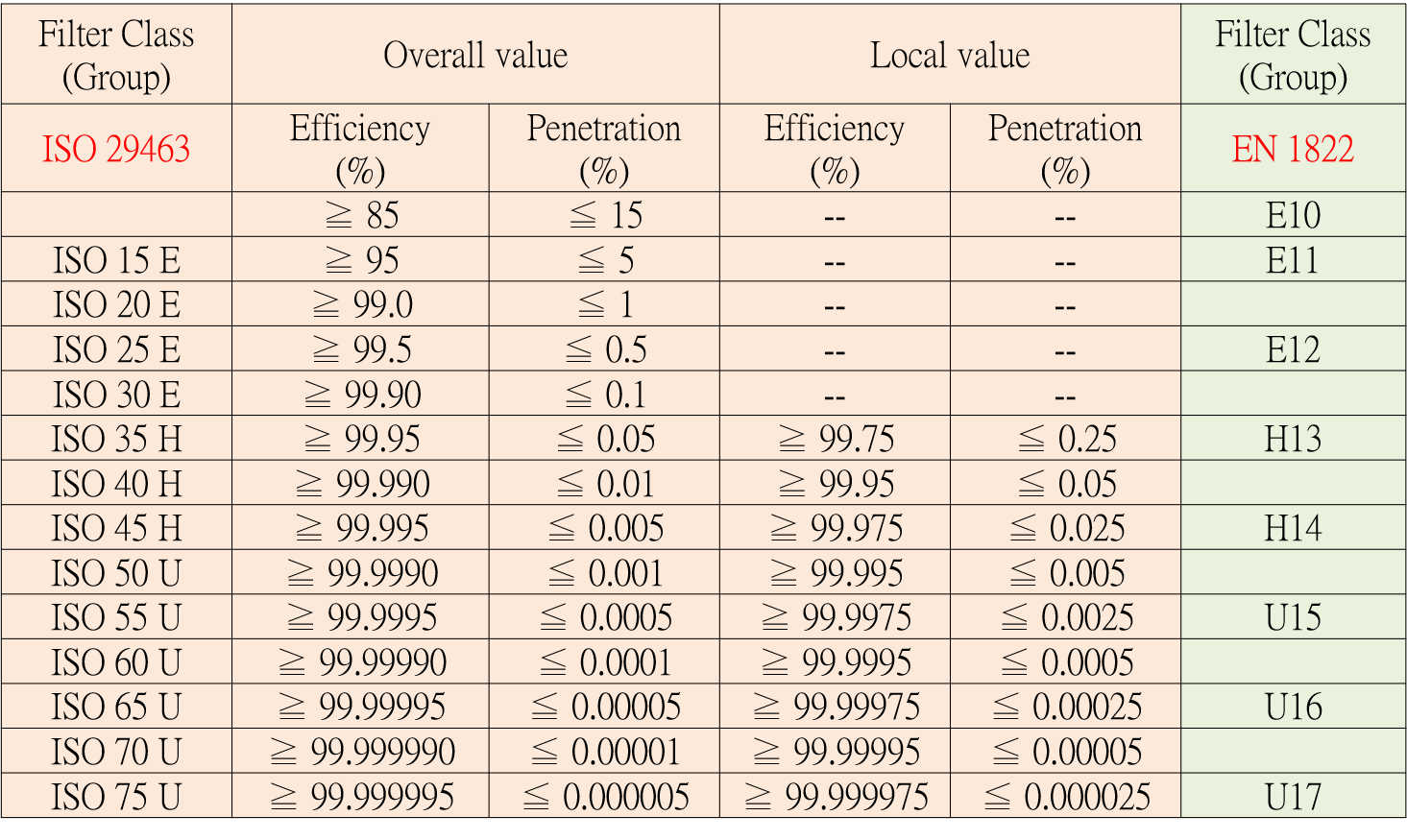

EPA, HEPA and ULPA air filter testing standards

EN 1822 (ISO 29463:2011) High efficiency air filters (EPA, HEPA and ULPA)

Part 1 : 2019 – Classification, performance testing, marking

Part 2 : 2009 – Aerosol production, measuring equipment, particle counting statistics

Part 3 : 2009 – Testing flat sheet filter media

Part 4 : 2009 – Determining leakage of filter element (Scan method)

Part 5 : 2009 – Determining the efficiency of filter element

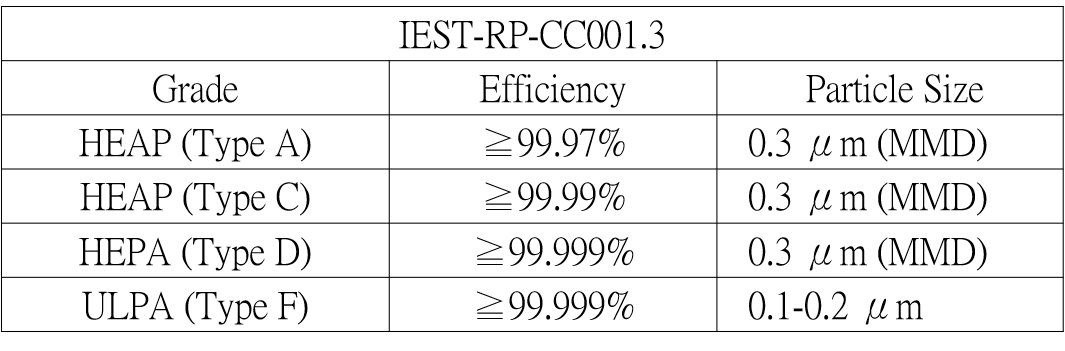

IEST-RP-CC001.5 :2009 HEPA and ULPA Filters

IEST-RP-CC007.2 :2007 Testing ULPA Filters

IEST-RP-CC021.3 :2009 Testing HEPA and ULPA Filter Media

IEST-RP-CC034.3 :2009 HEPA and ULPA Filter Leak Tests

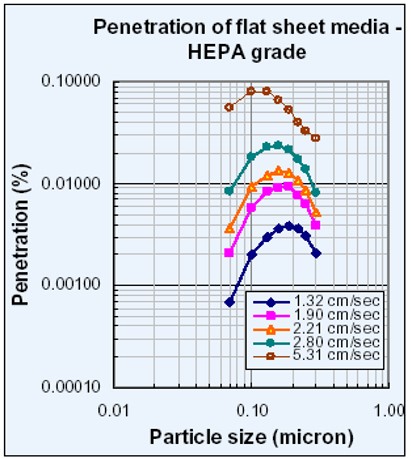

EN 1822-3 filtration media

Measuring the initial efficiency at different particle size and obtain the minimum efficiency at most penetration particle size (MPPS). The available maximum filtration efficiency can be up to 99.99999%.

Testing procedures of HEPA/ULPA air filter (EN 1822)

1. Determin the air flow rate or face velocity

2. Calculate the effective area of filter media

3. Calculate the media velocity

4. Measure the initial efficiency at different particle size and obtain the minimum efficiency at most penetration particle size (MPPS)

Classification